Custom Waterjet Work in

Abrasive Waterjet Cutting

Waterjet cutting, uses a high-velocity, high pressure stream of water often combined with a powdered abrasive, such as garnet to increase cutting ability of various materials. Waterjet can cut any material, including paper, cardboard, glass, graphite, epoxy, fiberglass, plastic, titanium, aluminum, carbon & stainless steel.

Because no heat is involved, no heat-affected zone is produced, eliminating warping, cracking and the need for many secondary operations. The omni-directional capabilities of the waterjet stream facilitates cutting precise contours, intricate shapes, sharp corners and low bevel angles not possible with most machine tools.

Specifications

Model: ESAB HYDROCUT-PR

Cutting Width: 5 feet

STD Cut Length: 10 feet

Waterjet height: 4 inches

Machine speed: 0.1-1000 IPM

High Precision Plasma Cutting

Precision plasma, as the name implies, is a highly precise form of plasma cutting in which proprietary arc technology constricts the plasma stream to make a low dross, low bevel angle cuts. The resulting cut face, when using precision plasma, is very smooth.

This process is commonly used to cut carbon steel, stainless steel and aluminum up to 2 inch thick. Precision plasma can be combined with oxy-fule or conventional plasma on a single gantry, allowing for a wide variety of applications. Also, this is cut underwater to avoid the heat factor for warping and cracking.

Specifications

Model: ESAB HYDROCUT-PR

Cutting Width: 5 feet

STD Cut Length: 10 feet

Waterjet height: 4 inches

Machine speed: 0.1-1000 IPM

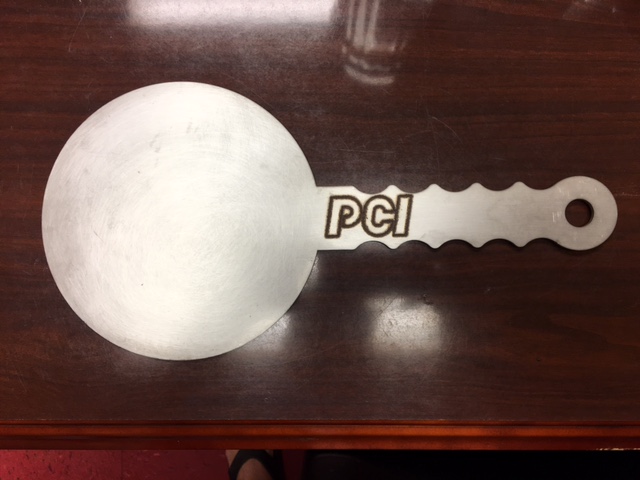

Blind for Flange

Choo Choo

Sign

Star Wrench

High Precision Plasma Cut of Outside and Waterjet Holes